Why KUK?

COIL EXPERTISE THROUGH CLIENT SUCCESS

The proof of our competence and proficiency in coil winding and manufacturing is not found in any off-the-shelf product, but rather in the successful stories of our contented customers who have utilized our knowledge and capabilities. These stories exemplify how our skills have been put into practice and achieved favorable outcomes for our partners.

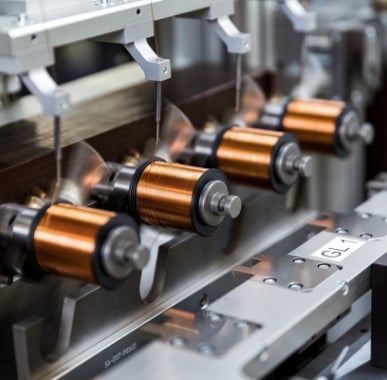

Within a few months, KUK Coils has set up series production for solenoid valves in several variants. An automotive tier-2 supplier benefits from the rapid ramp-up of series production as well as the flexibility of the self-developed production line: two different products in a total of five variants can be manufactured there.

COMPLETE SOLENOID VALVES FROM ONE SOURCE

Project:Custom coil production for automotive Tier 2 supplier

Know-how:

Installation interlinked full automation, insert molding bobbin, winding, overmoulding solenoid valve

Advantage:

Rapid series ramp-up, high flexibility

FLEXIBLE COIL PRODUCTION FOR LABORATORY TECH

INTEGRA Biosciences sets the standard for laboratory technology companies by sourcing customer-specific coils and PCB assembly from a one-stop-shop. INTEGRA recently received excellent support in coil production for a state-of-the-art laboratory pipetting device, demonstrating their commitment to innovation and efficiency.

ADVANCED RFID COIL FOR SAFETY APPLICATION

KUK Coils provided crucial support to Elesta GmbH, a Swiss technology company, in developing an advanced functional safety sensor. The exceptional quality of the RFID coil was just one aspect of KUK Group's impressive dedication throughout the various stages of the project.

LINEAR MOTOR ENABLES TOP PERFORMANCE IN MEDTECH

KUK patent coils optimise the performance and reliability of a linear motor for a game-changing medical technology application. A laboratory system from Hamilton Bonaduz impresses with very fast dispensing in an exceptionally large volume range. Fluid consumption is reduced, while at the same time the working speed is increased.

SMOOTH OUTSOURCING OF HANDPIECE FOR EYE SURGERY

The collaboration with KUK Coils is an enormous relief for us.

Martin Bürki, founder and partner Bürki inno med

PRODUCT HIGHLIGHTS

/Micro%20coil%20air%20core%202.png?width=540&height=304&name=Micro%20coil%20air%20core%202.png)

Micro coil (Air core)

The production of miniature air coils or micro coils is one of KUK's specialities. According to your specific requirements, we process ultra-fine wires from a diameter of 0.020 mm.

/Micro%20coil%20on%20core%202.png?width=540&height=304&name=Micro%20coil%20on%20core%202.png)

Micro coil (Magnetic core)

The production of micro coils with magnetic cores is one of KUK's specialities. We have established a great deal of know-how in handling windings directly onto magnetic cores.

Windings on customer-specific bobbins

KUK offers windings on customer-specific coil formers with all common bobbin shapes and geometries. All conceivable shapes of electric coils are customer-specific manufactured.

READY WITH A NEW PROJECT?

Our experts for coil and electronics manufacturing will be pleased to advise you.