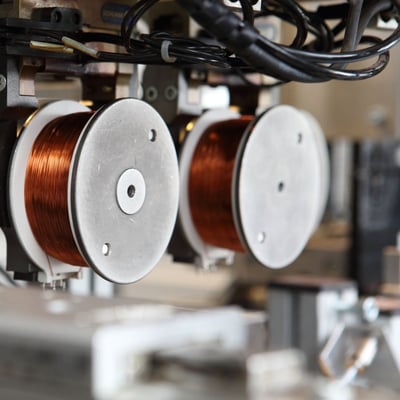

Overmoulding / Insert Molding

OVERMOULDING YOUR COILS AND ASSEMBLIES

In overmoulding or insert molding, a coil or assembly is overmoulded with a synthetic material in a further process step. In this way, the winding goods are optimally protected for harsh environmental conditions. This also improves product performance in particular.

OVERVIEW OVERMOULDING / INSERT MOLDING

- Insert molding of contacts

- Bobbin is coiled and winding is contacted

- Coil is insert-molded

- Test (e.g. through connectors) and labeling (retraceability) of the finished product

Overmoulding of winding goods and assemblies offers the following advantages:

- Improved product performance as the overmoulded coils ...

- have a higher chemical resistance

- become more resistant

- become more waterproof

- Durability and toughness

- Lower overall production costs as there is no need to assemble into a housing

- Flexibility in design

- Contacting/plug can be directly considered in design

- Simplified process flow

- Shorter process time with high automation

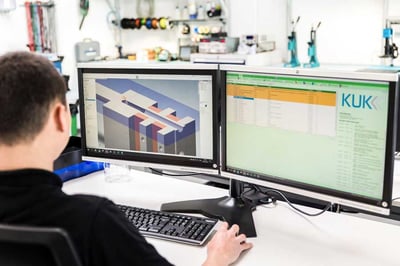

Customer-specific solutions are our speciality

Andreas Wild and the product team will be happy to advise you.

KUK offers you various customer-specific production steps for the assembly of modules:

- Electronics are added to coils or coil configurations, e.g. for motors (stator)

- Wire assembling

- Electronics (e. g. PCB) are assembled with electromechanical components into devices

- Potting of coils / modules

- Sealing of electronics / coil impregnation

- Insert molding of coils

Just winding coils is usually not enough, further production steps are necessary until an equipment manufacturer obtains a functional component. High flexibility and fast turnaround times are the biggest advantages for the customer. «At the end of the day, we assemble coil, PCB and cable into a complete motor. This is KUK's great competence,» states CEO Manuel Inauen.

As a system supplier, KUK is able to decide quickly on the entire manufacturing process without x partners being involved. The customer also benefits from KUK's established, global network of suppliers and thus from the best conditions. An equipment manufacturer, further away from its core business, also lacks the know-how in the procurement of certain individual parts.

OUR KNOW-HOW AND SERVICES

.png?upsize=true&upscale=true&width=72&height=72&name=settings(1).png)

Process partner from product idea to large-scale production

KUK serves the customer according to individual requirements from development phase to the integration of the goods into the global supply chain.

More

READY WITH A NEW PROJECT?

Our experts for coil and electronics manufacturing will be pleased to advise you.