Medical technology coil

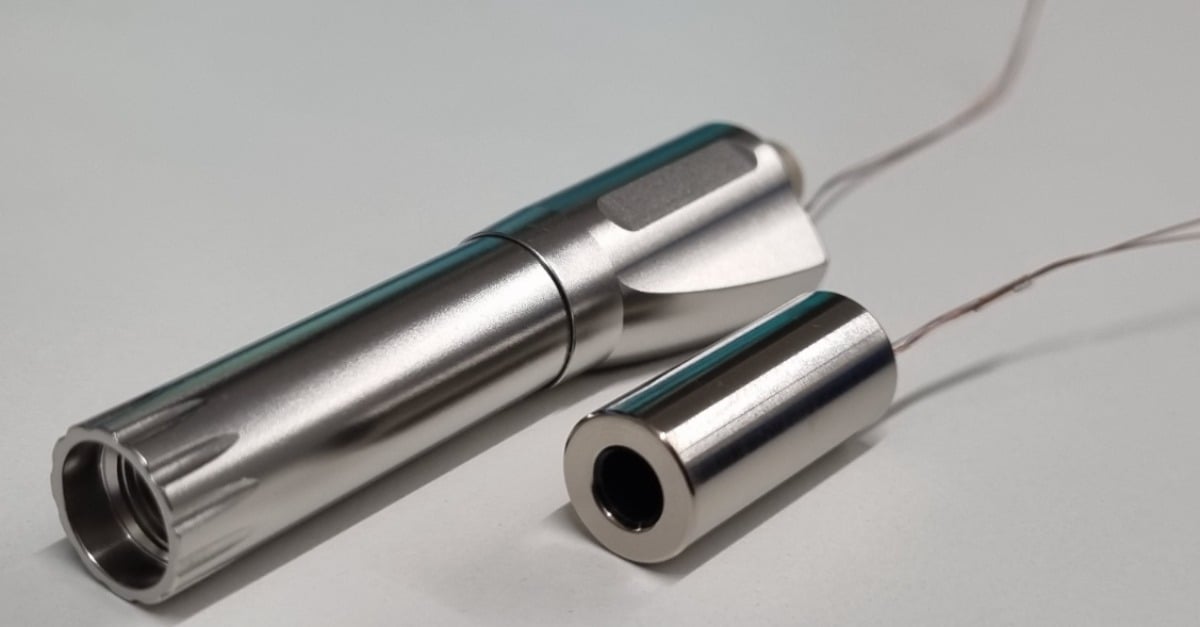

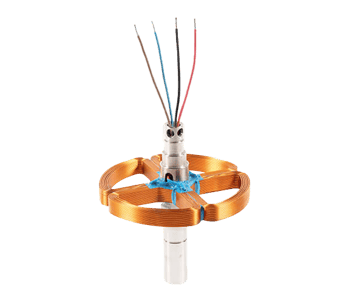

Wound coil produced by KUK Group, which is cast in the housing, for the medical technology manufacturer Bürki inno med.

Ready for series production in a few months

During the initial discussions, it became evident that KUK could take on another processing step: Assembling under the microscope with the specification that the coil is hermetically sealed. In this highly sensitive medical technology environment, applications must be autoclavable. Bürki inno med was able to rely on KUK's vast experience as a supplier to the medtech industry. "In addition to the quality with which we receive the high-precision component, we are particularly pleased that we found a supplier in the immediate proximity," says Bürki. He was also very satisfied with the extremely short lead time of the outsourcing: only a short time after the start of the project, he had the first samples in his hands, and after less than half a year, a first series of several hundred pieces followed. Thus, from A to Z, it is a successful coil project for a complex medtech surgical instrument.

RECOMMENDATIONS FOR COMPLEX COIL PROJECTS WITH MICRO COILS

NEW CHECKLIST

Engineers are the specialists for the development of highly complex medical devices. Time is short, the product launch is imminent, a successful coil project is urgently needed. Our checklist summarises some tips to help developers get the coils they need for their medical technology application in the timeframe they have in mind.

COIL MANUFACTURING AND EMS SERVICES FROM KUK GROUP IN THIS PROJECT

Windings on customer-specific bobbins

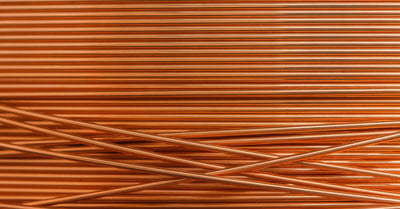

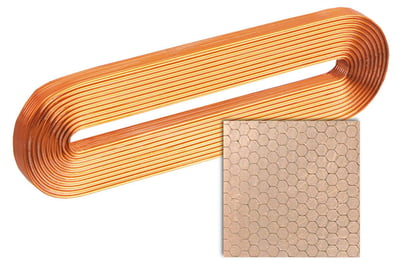

KUK offers windings on customer-specific coil formers with all common bobbin shapes and geometries. All conceivable shapes of electric coils are customer-specific manufactured.

Assembly of complete modules

In addition to the high level of competence in coil production, customers also value potting and assembly to stators or complete motors.

NEWS FROM THE PRODUCTION OF COILS AND ELECTRONICS

Insulation layer on magnet wires: A common stumbling block for engineers

What material can coils be wound from?

Self-supported coils: Facts about coils made of selfbonding wire

Misconceptions about the fill factor of electric coils

What is the advantage of orthocyclic windings?

Myths and facts on edgewise windings

READY WITH A NEW PROJECT?

Our experts for coil and electronics manufacturing will be pleased to advise you.