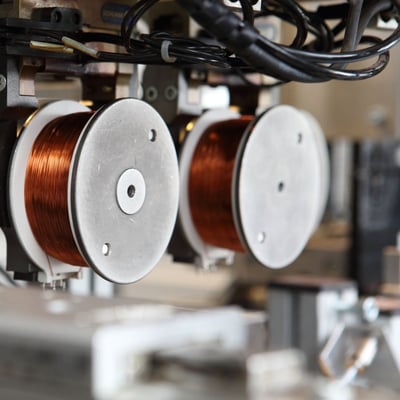

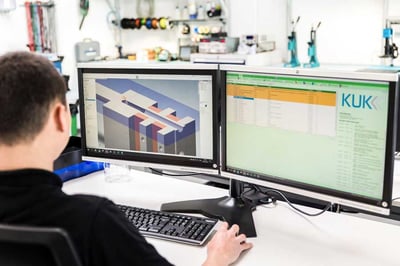

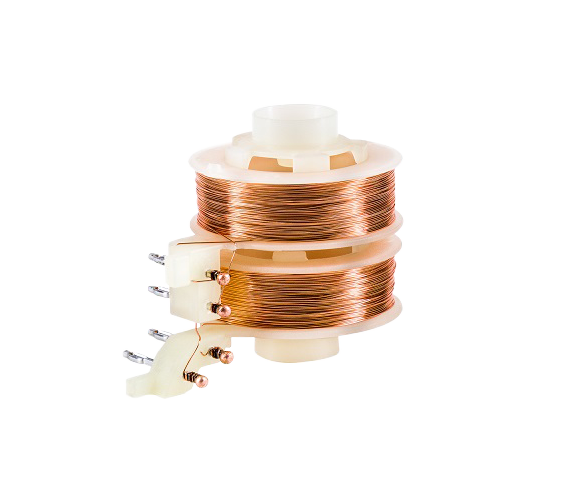

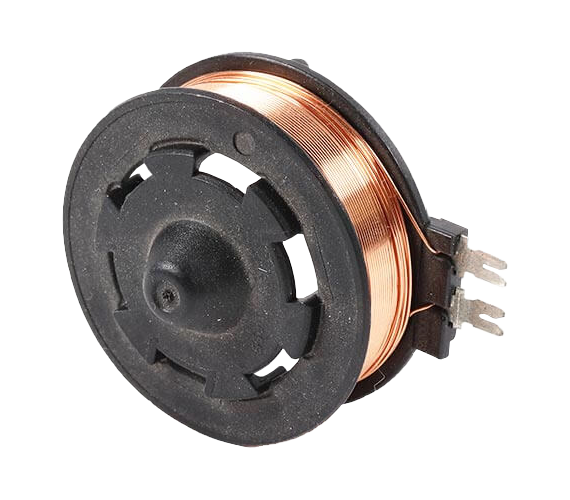

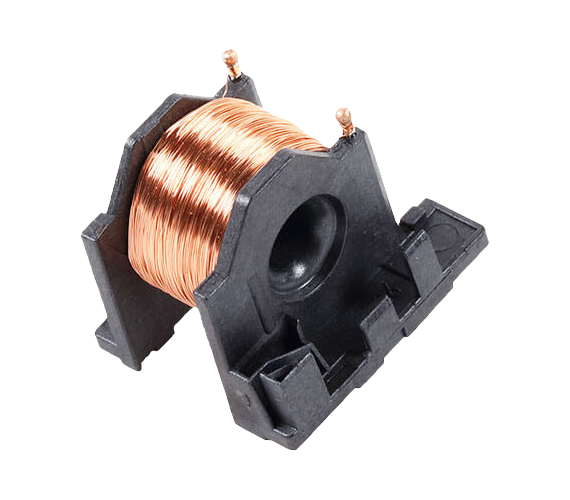

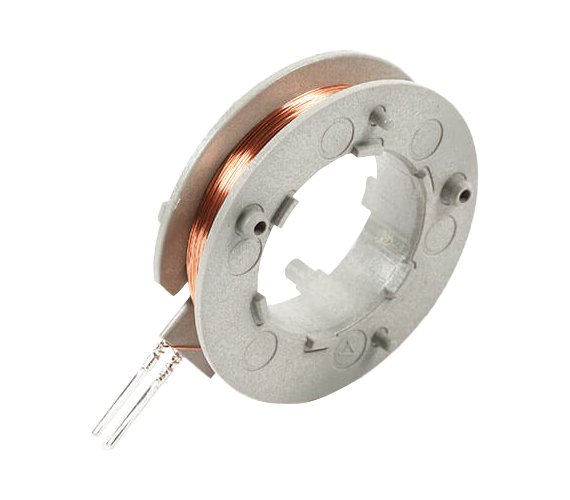

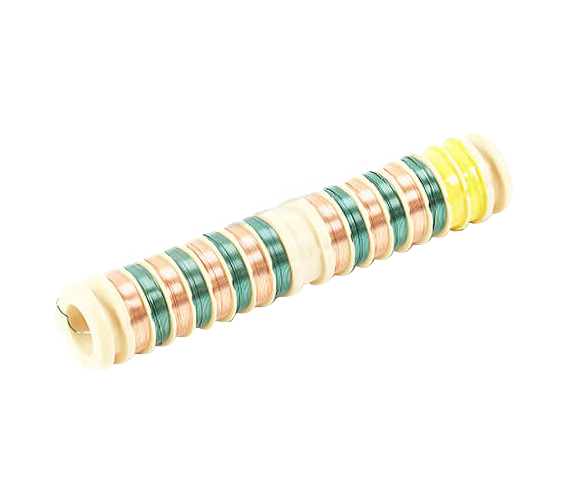

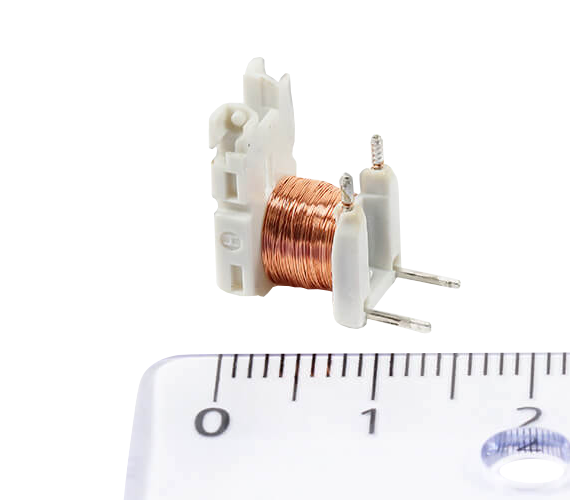

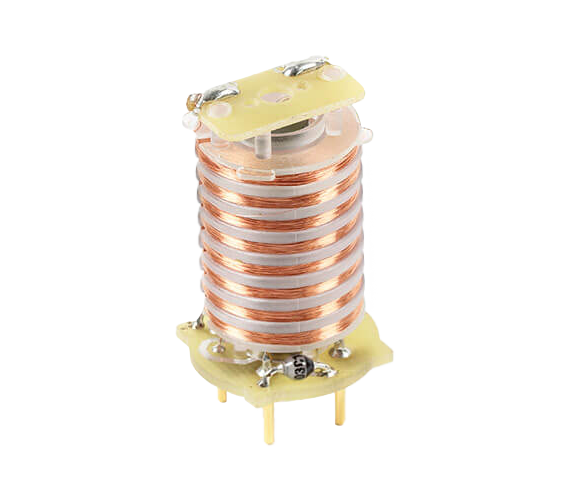

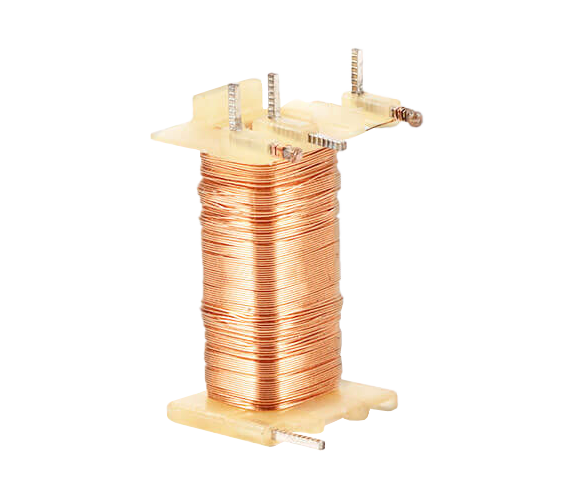

Windings on customer-specific bobbins

BEST COILS WITH OPTIMAL COIL FORMERS

KUK offers windings on customer-specific coil formers with all common core shapes and geometries. All conceivable shapes of electromagnetic coils are manufactured by us according to customer specifications. We are capable of winding on a wide variety of core materials. As a leading coil manufacturer, KUK processes all wire and litz wire types.

OVERVIEW WINDINGS ON CUSTOMER-SPECIFIC BOBBINS

- Different winding methods

- With molding pin

- With pin mounting

- Winding wire soldered, welded

- Insulation displacement terminals

- integrated Ferrite / Cores

- Different geometries

- Multiple chambers

- Size 3 to 400 mm

- With/without pins

- High temperature

KUK has a great deal of experience in winding coil formers with a wide variety of wires. Alternatives to copper wire are also possible.

- Varnished copper wires, strands

- Insulated wires

- Self-bonding wires

Customer-specific solutions are our speciality

Andreas Wild and the product team will be happy to advise you.

For bobbin coils, the ideal material depends on the respective application. KUK has a great deal of experience and can provide recommendations as early as the development phase. Coil formers matching the ferrite and made of highly qualified plastics in various design variants are also possible. KUK offers custom manufacturing for bobbin coils in all dimensions. Popular applications are for solenoids, actuators, stepper motors or linear drives.

When using customer-specific bobbin coils in applications, these advantages arise:

- individually tailored to your requirements

- In-house toolmaking

- high vertical range of manufacturing

- best wires for making solenoid

- one contact for all your requirements

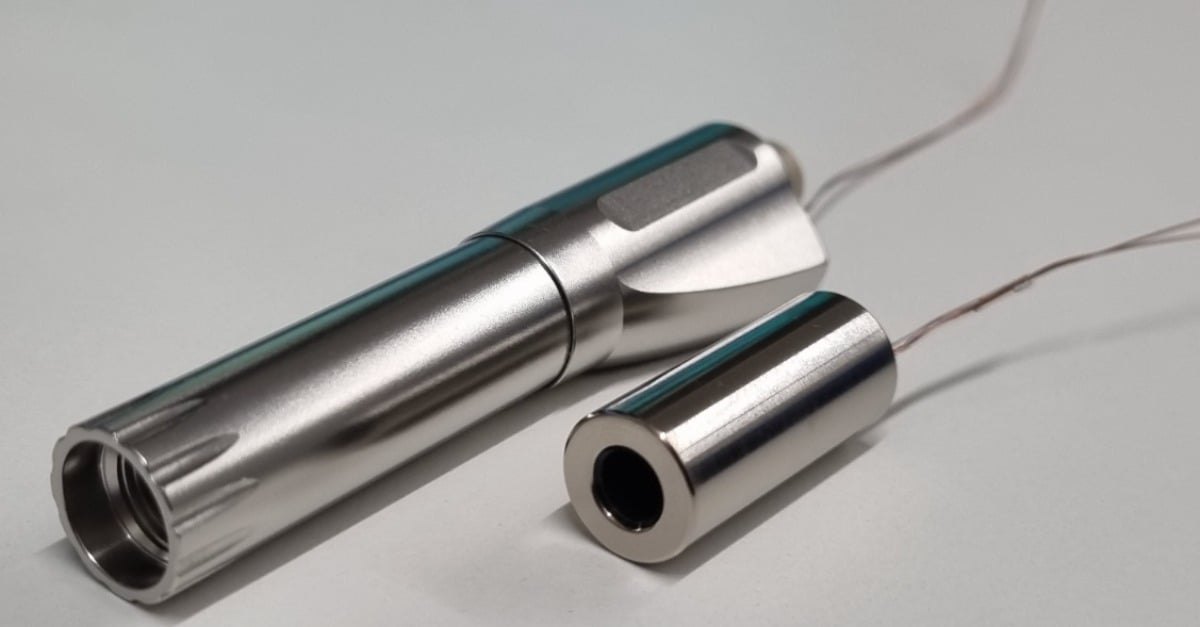

SMOOTH OUTSOURCING OF HANDPIECE FOR EYE SURGERY

The collaboration with KUK Group is an enormous relief for us.

Martin Bürki, founder and partner Bürki inno med

EXPLORING THE MANY APPLICATIONS OF SOLENOID COILS

Solenoid coils are versatile components that are used in a wide range of applications across many different fields. Here are some examples of where solenoid coils are commonly used:

Medical: Solenoid coils are used in medical devices, such as MRI machines, to generate magnetic fields for imaging.

Industrial automation: Solenoid coils are used in industrial automation applications, such as valve control, conveyor systems, and robotics.

Security systems: Solenoid coils are used in security systems, such as door locks and access control systems.

Automotive: Solenoid coils are used in automobiles for a variety of applications, such as fuel injection, transmission control, and engine management.

Find out here which requirements have to be taken into account in the design.

OUR KNOW-HOW AND SERVICES

.png?upsize=true&upscale=true&width=72&height=72&name=settings(1).png)

.png?upsize=true&upscale=true&width=512&height=512&name=delivery(1).png)

Process partner from product idea to large-scale production

KUK serves the customer according to individual requirements from development phase to the integration of the goods into the global supply chain.

MoreREADY WITH A NEW PROJECT?

Our experts for coil and electronics manufacturing will be pleased to advise you.