Competences

PARTNER FROM PRODUCT IDEA TO LARGE-SCALE PRODUCTION

Since KUK Group manufactures winding goods exclusively according to the customer's requirements, we know which milestones have to be reached from the product idea to the release of series production. In addition to development and production, KUK also sees itself as a partner for the customer's global sourcing and logistics. Ultimately, you will find the result of our capabilities and skills not in any catalog, but in the applications of our satisfied business partners.

OUR PROCESS

FEASIBILITY

Whether a specific coil or electronic component can be manufactured according to the customer's wishes must be clarified before the offer is submitted. Depending on the specifications, the effort involved can range from a simple technical assessment to a comprehensive FMEA. In the case of enquiries that involve completely new requirements, a test setup can also be carried out with the customer.

KUK is prepared to tackle or accompany new developments. For KUK, each winding good or electronic component is unique, but based on many years of experience, KUK is the ideal partner already in the feasibility phase. The in-house developers are familiar with the challenges in the development stage.

OPTIMIZATION

Winding goods and assemblies according to customer specifications are the goal. To achieve this, KUK can draw on many years of knowledge in the adaptation of systems and devices.

KUK's interdisciplinary (mechanical engineering, electronics, automation) development department has broad experience in the optimisation of products from a production engineering perspective.

KUK is oriented towards the customer's ideas of function, quality and price. In-house or in co-engineering with the customer, quantities and variants are discussed until the best variant emerges.

SAMPLING

In many cases, coils and assemblies are still sampled in order to be able to test the actual performance at the customer's site. These samples can be produced within a very short time. In order to be able to assess the production process already at this stage, the required tools are manufactured at a level as close to series production as possible.

Each sampling is accompanied by the same developer who defined the production process in advance. All critical features are immediately recorded and the process is directly adapted wherever possible. The customer receives a detailed initial sample inspection report that includes all features assessed as critical by the customer or KUK. For products in the automotive industry, a PPAP process is carried out as standard.

AUTOMATION

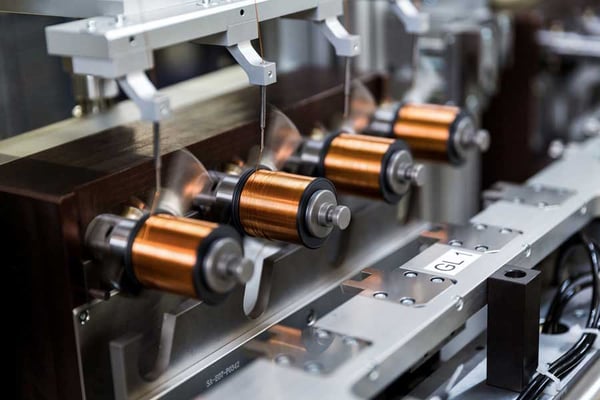

Each line is designed and built by the in-house automation team to meet the requirements of the product. The goal is always efficient, high-quality and cost-effective series production that can be ramped up after six months at the latest.

Automation makes commercial sense, especially for large quantities. Processes such as the production of air core coils, windings on bobbins, overmoulding, contacting and many others can be automated. KUK Group can draw on a wide range of experience in this area. The corresponding systems are used and maintained at all KUK locations

SERIES

KUK manufactures winding goods and assemblies in any series size. Series production also includes arrangements regarding design changes, packaging and logistics or capacity planning. At the customer's request, KUK manages the complete procurement for the end product, for example for mechanical components or supplementary purchased parts.

The introduction of series production is permanently monitored by the development and quality department. All employees can access the proprietary production data management software (PDM) via tablet PC. It is possible to define inspection criteria for any work step during series production.

SCALING

Production sites on different continents as well as the in-house automation department ensure flexibility for rapidly increasing demand. Even at the design stage, care is taken to ensure that the production facilities can be flexibly duplicated or expanded, so that rapid scaling is guaranteed. The same applies to the production of product variants on the same line.

The global network of established suppliers enables timely and competitive procurement even in the event of rapid volume increases.

Customer-specific solutions are our speciality

We are happy to support you from the development stage onwards so that together we can find the best manufacturing solution for your products.

DEVELOPMENT

KUK supports the customer from the development phase onwards, because as a technically leading coil and electronics manufacturer, we know what is important: short response times, agile engineering and proactive alternatives on the table. In doing so, KUK draws on many years of experience in connection technology as well as in the design of coil formers, assembly parts and electronics.

AUTOMATION

At KUK Group, customer-specific coils and electronic assemblies are largely produced on automated lines developed in-house. This means that we can offer you a very attractive coil production process in terms of quality and commerce, tailored to your volume and technical specifications.

Quality is the top priority at KUK, which applies to our products and processes alike.

- ISO 14001 and IATF 16949 certifications

- Systematic use of quality tools

- Systematic monitoring and calibration of testing equipment

- Individual testing level determined by the product or the process

QUALITY MANAGEMENT

Our success is founded on the highest product quality at a Swiss level across all locations. That's why we are continually refining our production processes, optimising productivity and increasing efficiency. The production data management system developed by KUK in Appenzell guarantees the highest quality at all seven locations at global market prices.

As part of our integrated management system, we guarantee the documentation and continual optimisation of our workflows and structures. The essential certifications distinguish KUK as a reliable partner for automotive, industry and medicine & sensor. You can trust our quality awareness!

READY WITH A NEW PROJECT?

Our experts for coil and electronics manufacturing will be pleased to advise you.